- Washing and cleaning with 600 bar and 2500 bar high-pressure washers, industrial water vacuum cleaners.

- 1 m3 plastic tank park for storing and transporting hazardous materials.

- Safety equipment for carrying out the work: fresh air system operated by an external compressor, chemical protective clothing and protective gloves, 15-liter oxygen bottles for safe exit of the tank in case of emergency shutdown.

- All of our employees have the necessary entrance exams to perform their work professionally.

- Final inspection of the washing and cleaning performed and documentation of the work processes in the quality assurance system.

Inspection of tank body, detection of defects.

- Repair of tank body defects, execution of locksmith and welding works.

- Inspection of tinned surfaces, detection of defects.

- Re-plating of defective tinned surfaces.

- Inspection of gratings and ladders, detection of errors.

- Repairing defects in walkways and ladders, and carrying out locksmith and welding works.

- Inspection of anti-theft elements, detection of faults.

- Pre-production, repair and welding of faulty, missing anti-theft elements.

- Final inspection of completed work and documentation of work processes in the quality assurance system.

- Revision of tank wagon fasteners, detection of rust defects and missing elements.

- Dimensioning of replacement fasteners with the appropriate certified measuring instruments.

- List of replacement fasteners.

- Removal of worn fasteners without damaging painted and rubberized surfaces.

- Inclusion of the new fasteners (Acid-resistant A2, A4, galvanized 5.6, 8.8) in accordance with the requirements of the partners from the Kanban screw system established in the area.

- Installation of the new fasteners with the certified tools, tightened to the specified torques.

- Final inspection of installed screws and documentation of work processes in the quality assurance system.

- Inspection of the rubberized surfaces of the tank wagon, detection of cracks, defects due to wear and tear of the rubber, missing rubber surfaces.

- Re-rubbering the interior of the complete tank wagon according to the partner’s request.

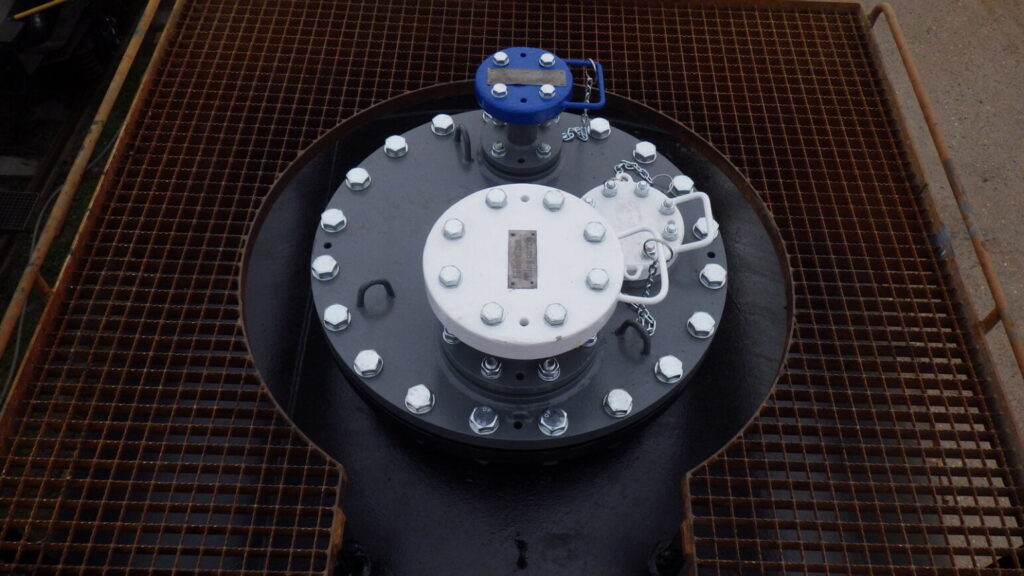

- Re-rubbering of tanker parts, which can be: Dome covers, submersible pipes, valve seat, DN150 submersible stubs, DN600 manholes, DN50, DN80, DN150 blind flanges, dome cover risers (extensions), valve stems, valve stem operating covers, lower drains, T period.

- Fully rubberization of newly manufactured tank wagon.

- Final inspection of rubberizing works and documentation of work processes in the quality assurance system.

- Inspection of the painted surfaces of tank wagon, detection of corrosion defects, pitting and wear.

- Repainting of the complete tank car according to the partner’s request.

- Surface treatment of tanker parts with sandblasting (granite sand), which can be the following: Dome covers, submersible pipes, DN50, DN80, DN150 blind flanges, dome cover risers (extensions), valve stem operating covers, bottom drains, T branches, central valve, valve seat, tilting cover, rescuers.

- The tanker parts that need to be painted are painted with special paints prescribed by the partners, which can be the following: Dome covers, submersible pipes, DN50, DN80, DN150 blind flanges, dome cover risers (extensions), valve stem operating covers, bottom drains, T branches, central valve, valve seat, tilting cover, rescuers.

- Final inspection of painting works and documentation of work processes in the quality assurance system.

- Inspection of the tank wagon, detection of worn and missing inscriptions, stickers, signs and expired exam dates.

- Production of the required stickers, painting templates, and signs as required.

- Sticking and installing the new stickers, painting templates, signs, and painting the exam marks using templates.

- Final inspection of stickering, labeling and examination mark painting works and documentation of the work processes in the quality assurance system.

- Tank wagon pressure test with water.

- Tank wagon pressure test with air.

- Final inspection of tank wagon.

- Documenting the pressure test and final inspection of tank wagon in the quality assurance system.

IMPORTANT INFORMATION:

- The inspection and repair of the chassis superstructures, chassis and wheels of the tank wagon that come to us is carried out by an external partner.