From 16.10.2023, our range of activities was expanded with our newly started automatic powder coating System.

DESCRIPTION

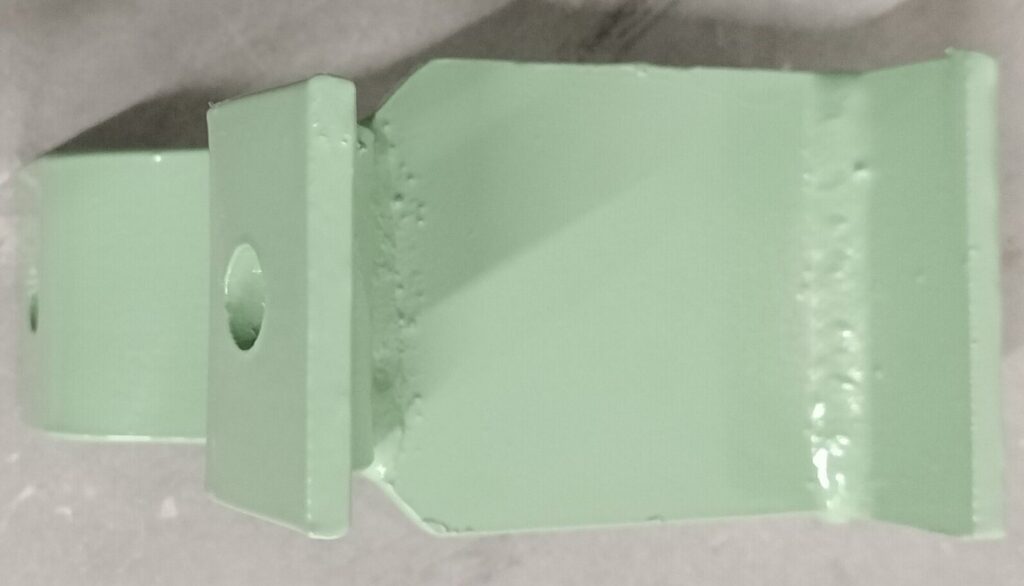

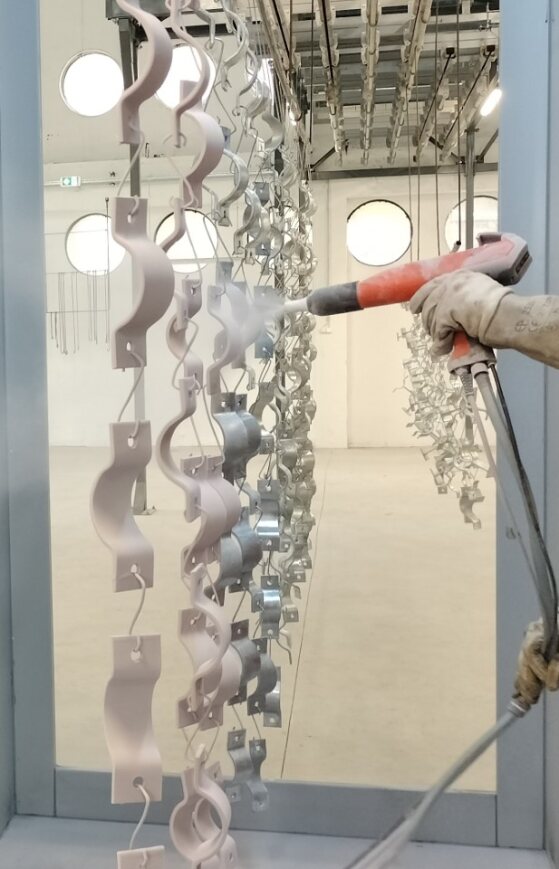

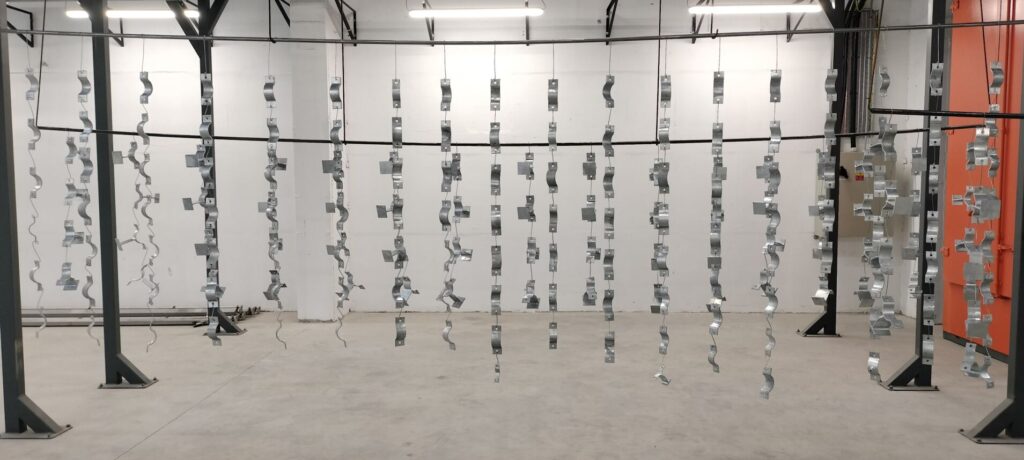

Powder painting or sintering is the metalworking process in which the plastic-based paint is applied in the form of dry powder to the surface to be painted and then burned. In electrostatic painting, the first phase is always the cleaning and pretreatment of the surface, which can be done mechanically or chemically. Only then does the powder coating process begin. The essence of powder painting is that a colored powder-based paint is applied to the surface with electrostatic spray guns at high voltage. The plastic-based powder paint adheres to the metal surface, and then at high temperatures, depending on the type of paint, for approx. It is baking at 160–200 °C. During baking in the oven, the powder paint is cross-linked on the metal surface, resulting in an extremely durable, homogeneous, flexible and heat-resistant surface coating.

Technological advantages:

The powder coating process is a closed technology with no harmful emissions and no use of solvents. Powder coating is also suitable for quickly coating large surfaces. In the case of powder coating, there is no drying time, the product coated with sintering can be used immediately after firing. Thanks to the use of high-quality raw materials, the coating will be extremely resistant.

ELECTRON AUTOMATIC POWDER COATING EQUIPMENT

feed size:

Length: 6000mm

Height: 2500mm

Width: 1500mm

Load capacity: maximum 500kg

CLOSED SYSTEM CHEMICAL

PRE-TREATMENT

CABIN AND DRYING CABIN

HIGH QUALITY RAW MATERIALS USED FOR OUR TECHNOLOGICAL PROCESSES

CHEMICAL PRE-TREATMENT

POWDER COATING/SINTERING OUR INNOVATIVE MATERIAL PROTECTION SYSTEMS

METALPHOS 2330

Multi-metallic iron phosphating agent for spraying and high-pressure spraying applications.

DEXADD 60

Free acidity reducing additive for zinc and iron phosphating baths.

You can choose from a huge selection of colors in our RAL Classic system.

OUR PAINT SYSTEMS

AXALTA Plascoat PPA 571

AXALTA Alesta ZeroZinc Primers

AXALTA Alesta SD powder coatings

OUR PARTNERS:

WHAT WE OFFER…

Aluminium, steel and galvanized steel structures, fiber materials, building industry elements, air-technical devices, metal furniture, furniture parts, vehicle industry items, e.g. powder coating of rims and products manufactured for other areas of use.

You can choose colors from our wide RAL range in the shade that suits you best. From the palette, you can choose matte,silky, shiny, metallic shiny, smooth, and alsostructured surfaces.

Weather, heat-resistant and UV-resistantsurface treatments suitable for both outdoorand indoor use. On request, we undertake phosphatepretreatment and degreasing according to your needs.

In each case, we can provide our prices with individual pricing according to the size, shape, thickness of the surface to be treated, and the types of colors requested.